usp class vi elastomers

However some applica-tions such as implantable devices are extremely complicated. Medical field needs a wide range of products like prosthetics lubricants molds with superior class of chemical and thermal resistance.

![]()

Usp Vi Silicones Fda Approved Pronat

Centrifuge Tube - Virgin Polypropylene meets USP Class VI requirements for plastic containers and closures.

. Provides a high-level introduction to elastomer chemistry manufacturing technology and the post processing of components 3. PlasticsToday Staff Sep 17 2015 The flexibility durability neutrality and recyclability of the MT-1205I TPE make it a desirable alternative to PVC and thermoset rubber for medical tubing according to Polymax. The transparent elastomer is a high-purity compound with low leachables and extractables as required by the USP Class VI standard for ensuring patient safety.

7 USP Class VI materials. The central regulation for elastomer materials is contained in 21 CFR 1772600 - Rubber articles intended for repeated use. Master Bond offers a variety of USP Class VI approved UV curable compounds.

They also have models available that certify that no animal derivatives were used in the raw materials of the elastomer. UL FDA NSF USP Class VI ASTM JIS SAE MIL Specs RoHS Reach. In 1988 in vitro tests were explored and USP concluded that in vitro.

USP Class VI ISO 10993-5 Cytotoxicity In-Vitro Features Benefi ts. Class VI materials testing includes system toxicity and intracutaneous toxicity. Cap - Virgin High Density Polyethylene meets USP Class VI requirements for plastic containers and closures.

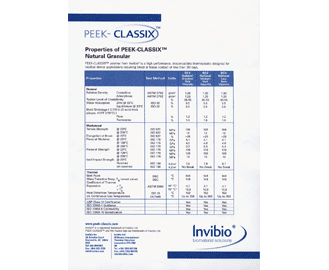

View substitute products 11-189-14. FAR 25853a for flame retardancy. Table 1 shows our standard programme FDA compliant com-pounds which can be produced in a few days.

Some end-users may also require that the O-rings be free from animal derived ingredients ADI free. CFR 1772600 USP Class VI to 70C 3-A Sanitary Standard 12 VMQ Si 70 W FDA 21. Testing There are two types of tests used by the USP for class VI O-rings and these apply to all elastomers plastics and polymeric materials.

Designates baseline requirements 5. Most applications are fairly benign to elastomers. In addition UV10TKMed also meets the ISO 10993-5.

Both ISO 10993 and USP Class VI define testing requirements for biocompatibility the ability of a material to perform a desired function without causing adverse effects on. Discusses identification testing A workshop Modernization of USP Packaging Standards for Glass and. Sil 714002 USP class VI Silicone 1 70 Yes transl.

Sil 714001 USP class VI Silicone 1 70 Yes transl. The USP Class VI approved elastomers are. Plastics were assigned Class I-VI based on the biological in vivo testing systemic injection intra-cutaneous and implantation tests.

For this reason the FDA provides a standard 21 CFR1772600 defining allowable rubber compound ingredients and extractibles based on toxicity and carcinogenicity. CFR 1772600 USP Class VI to 121C 9 12 FKM Vi 780 FDA 21. Expert seal design advice can be provided and components manufactured in the shortest lead times in the sealing industry.

FDA CFR 175300. Explains basic functional characteristics of components 4. This material is good in dry heat and has good ozone resistance.

Please call customer service for assistance. What is TPE. Ecdel 9966 elastomer meets ISO 10993 andor USP Class VI biocompatibility requirement Ecdel elastomers are plasticizer free copolyester elastomers COPE that offer clarity toughness flexibility and chemical resistance needed in a variety of flexible packaging including flexible medical and pharmaceutical packaging applications.

Stay Compliant with USP Class VI for your mass flow controller. Ecdel elastomers are plasticizer free copolyester elastomers COPE that offer clarity toughness flexibility and chemical resistance for flexible packaging including medical and pharmaceutical applications. These tests are the in vitro testing procedure and the in vivo testing procedure.

Please contact the division for assistance in selecting materials in these situations. Elastomer like silicon has widely used the material to build them and many other goods. The Brooks Instrument mass flow controller model SLA Biotech can offer certification of compliance with US.

ISO 9001 FDA USP Class VI. FDA And USP Class VI ORings Guide 2020 NES. Corning 500mL centrifuge tube polypropylene with accessories and dip tube Non-pyrogenic.

Sealable and weldable either pre- or post-sterilization C-Flex 072 provides prolonged pump life Sterilizable by gamma irradiation and autoclave Product Validation Test Summaries available upon request Moldable bondable and formable for single-use assemblies and overmolds Temperature. This item has been discontinued by the manufacturer and is no longer available. Pharmacopeia USPs Class VI standards for plastics.

Ia USP Class VI andor ISO 109933 will be required. USP Class VI silicones meet stringent biocompatibility requirements that are defined by the United States Pharmacopeia USP and recognized by the US. Both products are optically clear and they meet the USP class VI specifications.

PPE develops novel elastomer materials to meet the most demanding sealing applications including extreme temperatures and chemically aggressive environments. For most patient-contact applications a material that meets US Pharmacopeia USP Class VI andor ISO 109933 will be required. It is used in the assembly of medical devices and is capable of withstanding repeated sterilizations including radiation ethylene oxide chemical sterilants and especially autoclaving.

Silicone S0317-60 A red colored material that offers the widest temperature range of all the material choices - going from -65F to 400F. CFR 1772600 USP Class VI to 70C 11 Si 871 TR FDA 21. Moulded O-rings class 1 less than 10 furnace black These can be produced in all possible dimensions up to diameter 1400 mm internal.

UV10TKMed is USP Class VI approved and meets ISO10993-5 for cytotoxicity requirements. USP Class VI requires a systemic toxicity test an intracutaneous test and an implantation test all of which are directly related to the end use of the silicone article. FEPM Vi 602 FDA 21.

Most applications are fairly benign to elastomers. UL 1203 for explosion-proof. Ecdel 9967 may be processed on standard injection molding extrusion blow.

Tubing USP Class VI Thermoplastic Elastomer meets requirementsfor plastic containers and closures Female MPC and Polycarbonate meets USP Class VI requirementsfor plastics. Frequently Asked Questions FAQs. Food and Drug Administration FDA.

MIL-STD-810G for fungus resistance. UL 94V-0. Making certain assumptions including the assumption that the bonding area is completely accessible to UV light we can recommend UV10Med or UV10TKMed.

Based on the environment different elastomers can be recommended. Ecdel 9967 elastomer meets ISO 10993 andor USP Class VI biocompatibility requirement. 1965 USP XVII introduced Biological TestsPlastics Containers section was added and made official in the Compendium.

ISO 10993-5 for cytotoxicity. The elastomers like neoprene are perfect for this. Food and Drug Administration issues regulations for material in contact with food.

USP Class VI for biocompatibility. Inner Dimension - 0375. CFR 1772600 USP Class VI to 121C 3-A Sanitary Standard 9 10 12 Vi 971 W FDA 21.

MIL-STD-883J for thermal stability.

Meaning Of Usp Class Vi Standard United Kingdom

Usp Class Vi Seals Compliant To Food Grade Standards Barnwell

Meaning Of Usp Class Vi Standard United Kingdom

Usp Class Vi Seals Precision Polymer Engineering

Silicones Wacker Silicones For Medical Why Silicones Extremely

Usp Class Vi What Is It And How Does It Apply To Elastomers Barnwell

Usp Class Vi What Is It And How Does It Apply To Elastomers Barnwell

Fda Usda Nsf51 Usp Class Vi Compliant Seals Products

Silicones That Work Specialty Silicone Products Inc

Parker Medical Fda O Rings Sealing Devices

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group